superior corrosion protection without adding hydrogen embrittlement

A superior anti-corrosion coating – without adding hydrogen embrittlement

Hydrogen embrittlement has long been a serious hidden problem that can cause sudden premature failure in certain galvanized and zinc electroplated metal parts…

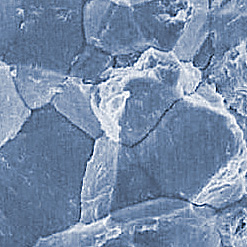

SEM: Hydrogen embrittlement

The problem begins when metals such as steel are exposed to hydrogen and the hydrogen atoms diffuse into the metal. Subsequently, the hydrogen atoms recombine into hydrogen molecules within small voids inside the metal, creating internal pressures. These cause the metal to become brittle and to fracture, which can lead to unexpected, rapid part failure.

Unfortunately, the acids used in various older processes such as galvanizing and zinc electroplating are common sources of hydrogen — and significant causes of added hydrogen embrittlement.

However, Greenkote adds zero hydrogen embrittlement…

Greenkote processing is acid-free

Greenkote® is a completely dry thermal diffusion process and very benign. It involves no acids or other sources of hydrogen, so it eliminates the problem of added hydrogen embrittlement in coated metal parts.

And, in addition, the elimination of acids and other hazardous chemicals also helps to make the Greenkote process greener and cleaner – far safer for humans and far friendlier for the environment.