Maximizing coating adhesion

Whenever multiple layers of metal coatings are being applied, coating adhesion is always a concern. But fortunately, Greenkote® provides a built-in solution…

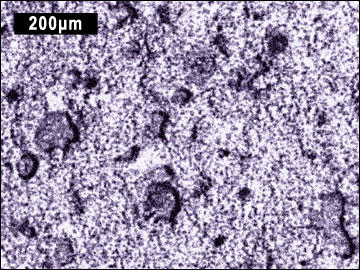

The unique microroughness of the Greenkote coating surface (see SEM image) naturally improves the adhesion of top-coat layers when it is used in primer or adhesive bonding applications. The surface roughness aids adhesion by giving “teeth” to the substrate and by increasing the total contact area between the layers. This increases the total interfacial or intermolecular attraction energy of the facing surfaces by a proportional amount.

In many cases, undercoating with Greenkote can eliminate the additional expenses of pre-treatment or surface roughening, which other processes often require to assist adhesion. And in addition to superior coating adhesion Greenkote provides excellent under-bond corrosion protection.

Greenkote coating is naturally compatible with one- and two-coat adhesive products used for molded rubber compounds made from natural and synthetic elastomers. It forms a hard surface that improves the coating adhesion of primers and adhesives to enhance bond strength and minimize undercut failures.

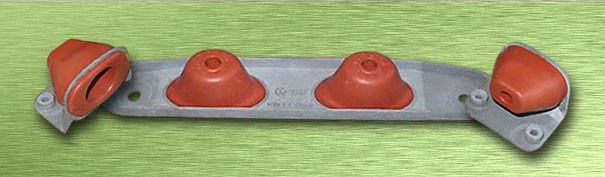

Application example: Rubber to metal molding

Greenkote PM-1 coatings are an excellent choice for corrosion protection in conjunction with subsequent rubber molding layers. The Greenkote surface does not require any blasting, roughening or priming before applying the rubber molding, and the coating provides a number of advantages:

- Strong direct coating adhesion for primer/adhesive topcoats

- Good bond strength without mechanical blast or phosphate

- Enhanced bond strength retention

- Reduced bond layer corrosion and undercut failure

- Superior performance in post-mold assembly — crimping, swaging, bending