Greenkote: the premier anti-corrosion metal coating

Metal corrosion is an extremely expensive global problem. Recent studies estimate that corrosion costs now exceed one trillion dollars per year in the US alone!

Zinc coating has long been the major means of protecting steels and iron-based metals from corrosion. However, the traditional zinc-coating technologies — electroplating, hot-dip, galvanizing — have each had significant issues. They have had limited corrosion-blocking effectiveness and they have also brought about serious ecological problems. Which is why Greenkote® was created…

Greenkote technology was specifically developed to address both of those issues: First, it provides superior anti-corrosion protection. And second, it is totally benign to the environment.

Corrosion-fighting technology

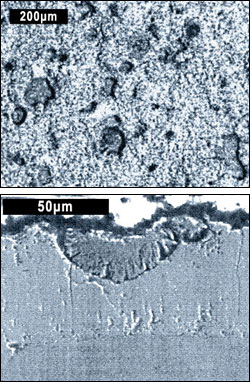

Greenkote’s thermo-chemical process forms a protective layer that partially diffuses into the substrate and cannot be easily separated by physical or environmental forces. The zinc in the thermal diffusion basecoat provides a high-performance, anti-corrosion sacrificial layer, while the unique aluminum inclusions on the surface (see SEM images) serve to heal any micro cracks or porosity in the coating. Corrosion protection is further enhanced by the unique microroughness of the Greenkote surface, which optimizes its adhesion properties for paint, electrocoat, powder coating and other topcoats.

Tested and proven

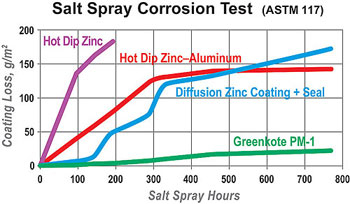

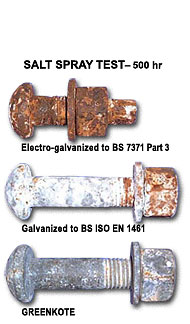

In 1000-hour testing, without sealers or special passivation layers, Greenkote proved to be resistant to neutral salt spray with a coating loss rate of less than 0.050 g/m2/hr. In addition, Greenkote is able to provide high quality anti-corrosion protection up to 400°C. The graph at right compares salt spray test results for different coating processes. It shows mass losses of various coatings in salt spray testing and illustrates the high corrosion resistance and extremely low Zn corrosion (white corrosion) rate of Greenkote PM-1 coating.

Greenkote is increasingly specified for high performance fasteners that require superior long-term corrosion resistance. For example, VW has qualified Greenkote PM coating with e-coat topcoat for its TL-196 specification “Duplex Coating for Small Parts” for corrosion protection. And Audi has approved Greenkote PM-10 plus e-coat for lock parts after it passed 60 cycles of corrosion testing.