state-of-the-art

powder coating

and electrocoating services

Greenkote — an ideal base layer

Among its many duplex system applications, Greenkote® can provide many synergies when combined with topcoats of powder coat or electrocoat (e-coat). Powder coating and e-coating are two industry-standard processes that can be applied either alone or in combination with Greenkote thermal diffusion undercoatings. For example, one of the world’s largest auto makers specifically calls for a duplex system of e-coat over Greenkote PM-10.

Greenkote facility, Queretaro, Mexico

Because of the importance of these technologies Greenkote operates a major, state-of-the-art facility under the trade name of Greenkote IPC that specializes in e-coating and powder coating services. This plant is located in Queretaro, Mexico, and serves both regional and international customers.

Electrocoating

Originally developed for the automotive industry, today e-coating provides high-quality finishes for everything from door strikers, hinges and brackets to larger stampings, tubing, fabricated assemblies and wire formed parts used in automotive, appliance, electrical, lawn and garden, office equipment, hardware and more.

One advantage of e-coating is that it can apply very thin, continuous film coatings on large volumes of product. The typical thickness for electrostatic coatings is from 2 to 5 mils. Greenkote’s e-coat processes employ lead-free cathodic black epoxy coatings for corrosion protection, applied in-line over a zinc phosphate pretreatment or as a topcoat over the Greenkote thermal-diffusion process. E-coating can also be used as a corrosion resistant coating by itself or as a primer coat for powder or other topcoat applications.

In Greenkote’s e-coating process, a clean metal part is submerged into a liquid e-coat bath of paint material that is charged with a positive current. As the negative-grounded part goes through the bath the positive coating particles migrate to the part until it becomes insulated from the current being applied. The part is then rinsed and sent through a curing process that evaporates the water from the film before it cross links and becomes a hard coating film that has excellent corrosion resistance.

Greenkote’s facility utilizes a slide-bar indexing e-coating system consisting of nine pretreatment stages, one e-coat stage, three post-rinsing stages, three drain stages and a 120-foot cure oven. Racking and un-racking areas are designed to process all products with maximum efficiency. At the final pre-packaging inspection station all parts are checked to ensure compliance with all quality specifications.

Powder coating

Powder coating applies a thermoplastic or thermoset polymer, in a range of colors; and it is usually used to create a finish that is tougher than liquid paint. Unlike paint, powder coating does not require solvents, which gives it significant ecological benefits. Powder has no hazardous waste, negligible VOCs and no air polution.

Application is by electrostatic spray. The powder is positively charged as it exits the spray gun, and as a negatively grounded part passes through the powder cloud the positive powder particles travel to the part. The part continues to coat until it becomes insulated from the voltage charge. The part is then sent through a cure oven where the powder melts and cross-links to form a hard final coating film with excellent corrosion and chemical resistance.

The Greenkote IPC powder coating line utilizes a 2,100-foot monorail conveyor system, with finely variable speeds. The pretreatment zone consists of eight stages followed by a dry-off oven and cool-down zone. The parts then enter the powder room which is equipped with two coating booths, each with 16 automatic oscillating electrostatic guns and four hand operated guns, to cover any difficult or recessed areas. Next, the coated parts enter a 600-foot natural gas cure oven, with IR booster capabilities for heavy parts. The parts then cool down before exiting to unload area where all parts are inspected and quality-checked prior to packaging.

A state-of-the-art operation

The Greenkote IPC operation specializes in powder coating and e-coating. Management has long years of experience specifically in these technologies, and the facility is uniquely designed for the work — which is why the facility offers a host of unique capabilities…

- Custom designed racks to accept any geometry of part

- Ability to coat complex shapes cost efficiently

- Full range of line speeds to accommodate any part size

- Choice of many powder-coat colors, rapid color change capability

- Rapid adaptability to different types of parts

- IR plus conventional oven systems, for faster processing of heavy parts

- Custom in-house rack stripping process

- Line design accommodates volume orders with superior cost-efficiency

- Flexible scheduling enables rapid response to priority production needs

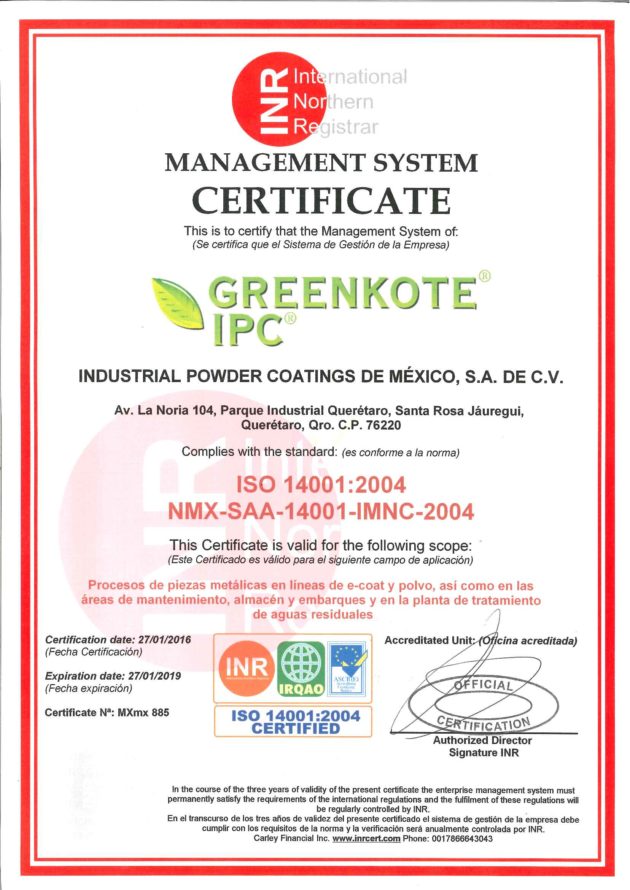

The facility has been ISO/TS certified and BOS indicators have been in place since 2005. The Greenkote IPC management system is also fully certified to the ISO 14001 standard. In addition, Greenkote maintains strategic supplier partnerships with all the major manufacturers for complete access to epoxy, polyester, acrylic, hybrid and special-formulation powders and all other needed materials.

Our aim is to always meet or exceed customer requirements, providing the highest quality, best delivery and most competitive pricing. This is why Greenkote IPC now enjoys a large customer base and excellent quality ratings from the major automotive companies and other industry OEMs.

Greenkote® and the Greenkote logo are registered trademarks of Greenkote PLC.